- $2,285.00

- $2,285.00

- Unit price

- per

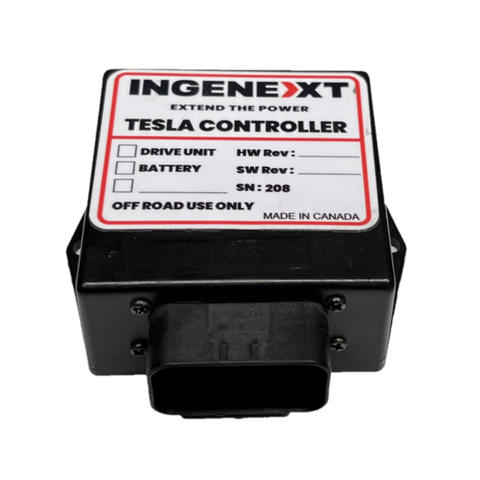

OUR CONTROLLER

Our controller allows you to use an RWD or AWD system, combined or not with the battery. For off-grid projects, you can select the battery option only.

PARTS

We can sell you your motor and battery. Contact us for more information.

SPECIFICATIONS

For off road only /

Remote programming included /

WARRANTY

1 year